Project Overview

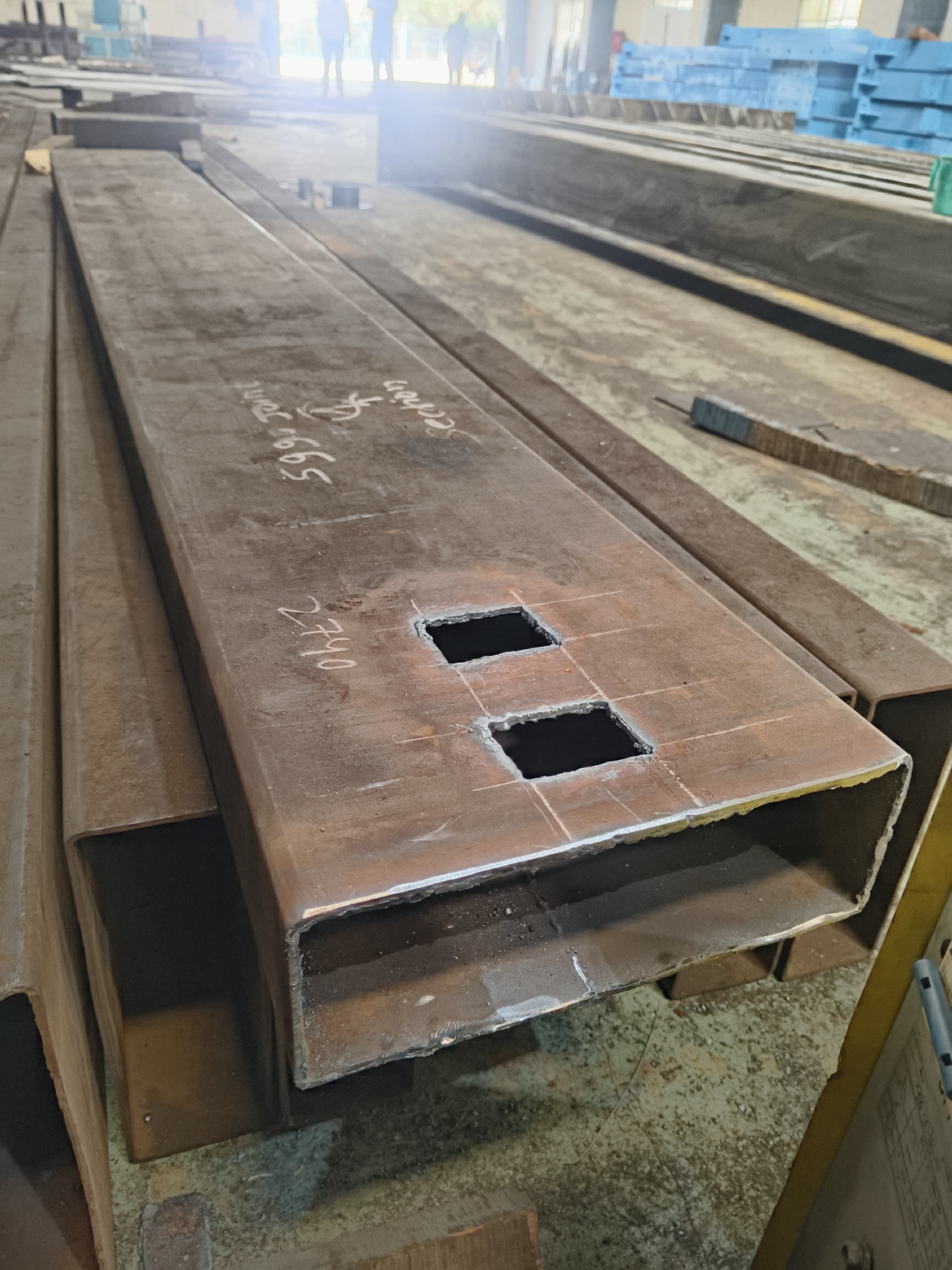

Vedant Infra successfully executed the Totem Beam Fabrication project for Godrej Properties, coordinated through Shreyash Construction. The project focused on delivering structurally strong, dimensionally accurate, and high-quality fabricated beams following a systematic manufacturing process.